Stainless steel tanks for water reservoirs formed by: deposit, mechanical float valve for the control of filling the tank, filter for impurities, minimum level switch, ball valvefor the aspiration hose of the group, drain valve installed at the lower part of the tank for maintenance, closing lid with air vent, connection hose to the pump and level view glass.

Polyester tanks reinforced with fibreglass (FRP) for water reservoirs formed by: deposit, mechanical float valve for the control of filling the tank, filter for impurities, minimum level switch, ball valve with connector for the aspiration hose of the group, drain valve installed at the lower part of the tank for maintenance, closing lid with air vent and connection hose to the pump.

| Reference | Capacity |

| AN/D500V | 500 |

| AN/D750V | 750 |

| AN/D1000V | 1.000 |

| AN/D2000 | 2.000 |

| AN/D3000 | 3.000 |

| AN/D4000 | 4.000 |

| AN/D5000 | 5.000 |

| AN/D6000 | 6.000 |

| AN/D7000 | 7.000 |

| AN/D8000 | 8.000 |

| AN/D9000 | 9.000 |

| AN/D10000 | 10.000 |

| AN/D11000 | 11.000 |

| AN/D12000 | 12.000 |

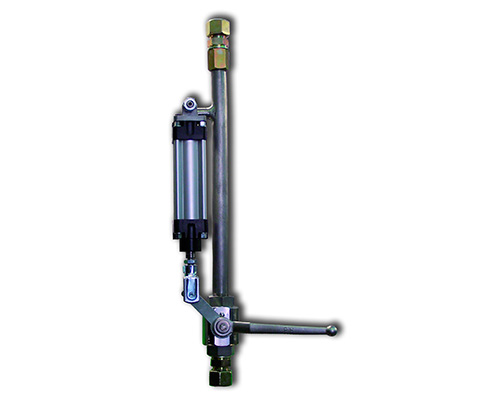

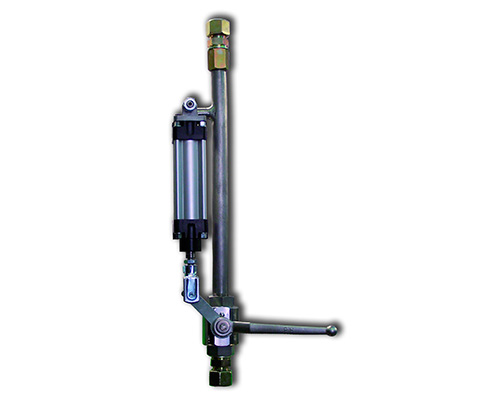

Normally closed high-pressure directional valve, formed by: ball valve of PN400 stainless steel, pneumatic piston, lever for manual opening, solenoid for electric triggering for the automatic opening and flanges for its fixation to the collector and aconnection to the installation tubes.

AN/VD38. Directional valve 3/8 diameter (inches)

AN/VD12. Directional valve 1/2 diameter (inches)

AN/VD34. Directional valve 3/4 diameter (inches)

AN/VD1. Directional valve 1 diameter (inches)

AN/VD114. Directional valve 1 1/4 diameter (inches)

Test run set for control until 14 valves

AN/AC. Fuse adapter for the fixation of diffusers

AN/ACA Fuse adapter for the fixation of anti-drip diffusers

AN/ACR Thread adapter for the fixation of diffusers

AN/VA Thread adapter for the fixation of anti-drip diffusers

AN/CTM. Stainless T-type union for fuse adapter

AN/CTR. Stainless T-type union for thread adapter

AN/CCOM. Union elbow swivelled, adjustable for fuse diffuser

AN/CCOR. Union elbow swivelled, adjustable for threaded diffuser.

Manufactured in AISI 304 stainless steel and designed for a working pressure of 280bar. In the open diffusers, the discharge is produced directly, when the water reaches them. This diffuser is suitable for the wet systems or as a pre-action.

The flow of the diffusers is depending on the model of the nozzle and their number and the flow can be selected from 0.6 L/min up to 36 L/min, with a pressure of 120 bar.

All the diffusers for fixed installations have the same thread and the same system of sealing. For the fixation of the diffuser to the tube, an adapter is used between the accessory of the tube and the diffuser.

Open nebulizer head for the installation in dry piping, made out of AISI 304 stainless steel special for high pressure, with the nozzles mounted at 90º, 120° or 160º and a rangeof flow rates sufficient to cover a wide range of risks.

| 4 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA120T4 | de 1,6 a 20,4 |

| AN/CA90T4 | de 1,6 a 20,4 |

| 5 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA120T5 | de 2,0 a 25,5 |

| AN/CA90T5 | de 2,0 a 25,5 |

| 7 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA120T7 | de 2,8 a 35,7 |

| AN/CA90T7 | de 2,8 a 35,7 |

Open nebulizer head for the installation in dry pipe, manufactured in AISI304 stainlesssteel for high pressure, equipped with 3 or 5 nozzles in line, in an angle of 180º.

| 3 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA180T3 | de 1,2 a 15,3 |

| 5 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA180T5 | de 2,0 a 25,5 |

| 4 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA360T4 | de 1,6 a 20,4 |

| 6 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CA360T6 | de 2,4 a 30,6 |

| 3 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CAP90T3 | de 1,2 a 15,3 |

| AN/CAP120T3 | de 1,2 a 15,3 |

| 4 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CAP90T4 | de 1,6 a 20,4 |

| AN/CAP120T4 | de 1,6 a 20,4 |

| 5 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CAP90T5 | de 2 a 25,5 |

| AN/CAP120T5 | de 2 a 25,5 |

Open nebulizer head for the installation in dry piping, manufactured in AISI304 stainlesssteel, for high pressure, equipped with 1 nozzle at an ideal diameter for kitchens,motors and special points.

| REFERENCE | FLOW (L/min) |

| AN/CA1T | de 0,4 a 5,1 |

Manufactured in AISI 304 stainless steel and designed for a working pressure of 280bar. In the closed diffusers, a discharge is only produced when the shutter bulb (fuse ) reaches the temperature that it was calibrated for. This diffuser is suitable for the wetsystems or as a preaction.

The flow of the diffusers is depending on the model of the nozzle and their numberand the flow can be selected from 0.6 L/min up to 36 L/min, with a pressure of 120bar.

All the diffusers for fixed installations have the same thread and the same system of sealing. For the fixation of the diffuser to the tube, an adapter is used between the accessory of the tube and the diffuser.

Closed nebulizer head with thermal bulb (fuse) that breaks at 57º and opens thenozzles, manufactured in AISI304 stainless steel, for its installation in high pressurewet tubes. They are equipped with 5 or 7 nozzles mounted in an opening angle of 90ºor 120° and a range of flow volumes sufficient to cover a wide range of needs.(Ask if the opening at other temperatures is needed).

| 5 NOZZLES |

| REFERENCE | FLOW(L/min) |

| AN/CC90T5 | de 2 a 25,5 |

| AN/CC120T5 | de 2 a 25,5 |

| 7 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CC120T7 | de 2,8 a 35,7 |

| 3 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CC180T3 | de 1,2 a 15,3 |

| 5 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CC180T5 | de 2,0 a 25,5 |

| 5 NOZZLES |

| REFERENCE | FLOW (L/min) |

| AN/CCP120T5 | de 2 a 25,5 |

Pumping equipment consisting of volumetric type electro pumps of ceramic pistons of a 40 L/min flow, pressure of 140 bar and a three-phase electric engine of 230/400V and 15 C.V (11.04 kw) each one of them, plus a centrifugal pump of stainless steel of 24 m3/h flow and 2 HP power, enough for the supply of 10 pumps. The pressure of feeding will be ensured by this feeding pump at 4 bar. The equipment is completed with a jockey pump with flow volume of 2.6 l/min regulated at a pressure between 30and 40 bar, with a 2 HP- 380 V three-phase electric motor. The electric control cabinetthat regulates the correct functioning of the equipment is designed according to the UNE 23500 norm and allows the emission of alarms at a distance.

The equipment consists of a pump controlled by a frequency variator and the others are controlled through soft starters. It is delivered assembled over a universal workbench, regulated according to the work pressure, depending on the project and its correct functioninghas been verified.

The pumping equipment is delivered with:

- Flexible high-pressure hose for the pumping, of 1½” and of 600 mm in length. Swivel connection, male thread size BSP 1½”.

- Aspiration hose of low pressure, of 2″ and 600 mm in length. Male thread connection size BSP 2″.

- Return collector of 3″ with flange connection DIN 2632/33.

| Reference | Flow Total (l/min) | C.V. total of the motors | KW total of the motors | Length(mm) | Width (mm) | Height H (mm) |

| AN/GAH3-40 | 120 | 50 | 38 | 1950 | 1400 | 1860 |

| AN/GAH4-40 | 160 | 65 | 49 | 1950 | 1400 | 1860 |

| AN/GAH5-40 | 200 | 80 | 60 | 1950 | 1400 | 1600 |

| AN/GAH6-40 | 240 | 95 | 70 | 1950 | 1400 | 2020 |

| AN/GAH7-40 | 280 | 110 | 82 | 1950 | 1400 | 2020 |

| AN/GAH8-40 | 320 | 125 | 93 | 1950 | 1400 | 2020 |

| AN/GAH9-40 | 360 | 140 | 105 | 1950 | 1400 | 2280 |

| AN/GAH10-40 | 400 | 155 | 116 | 1950 | 1400 | 2280 |

Pumping equipment consisting of volumetric type electro pumps of ceramic pistons of 40 L/min flow volume, pressure of 140 bar and a three-phase electric engine of 230/400V and 15 HP (11.04 KW).The electric control cabinet that regulates the functioning of the equipment is designed according to the UNE 23500 norm and allowsthe emission of remote alarms. The equipment consists of a pump controlled by afrequency variator and the other through a soft starter.

It is delivered assembled overa universal workbench, regulated according to the work pressure, depending on the project and has been verified its correct functioning.

The pumping equipment is delivered with:

- Flexible high-pressure hose for the pumping, of 1″ and 600 mm in length. Swivel connection, male thread size BSP 1″.

- Flexible high-pressure hose for the tests, of 1″ and 600 mm in length. Swivel connection, male thread size BSP 1″.

- Hose of aspiration at low pressure for the aspiration of 2″ and 600 mm in length. Connection male thread size BSP 2″.

| Reference | Flow Total (l/min) | C.V. total of the motors | KW total of the motors | Length(mm) | Width (mm) | Height H (mm) |

| AN/GAH1-12 | 12 | 5 | 3,68 | 1100 | 900 | 1750 |

| AN/GAH1-25 | 25 | 14,5 | 10,67 | 1100 | 900 | 1750 |

| AN/GAH2-25 | 50 | 27 | 19,87 | 1500 | 900 | 1750 |

| AN/GAH1-40 | 40 | 20 | 15 | 1100 | 900 | 1750 |

| AN/GAH2-40 | 80 | 35 | 26 | 1500 | 900 | 1750 |

|

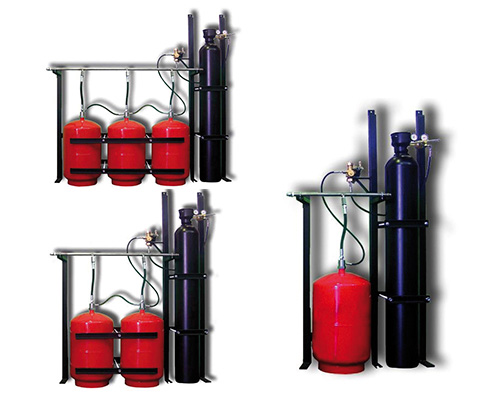

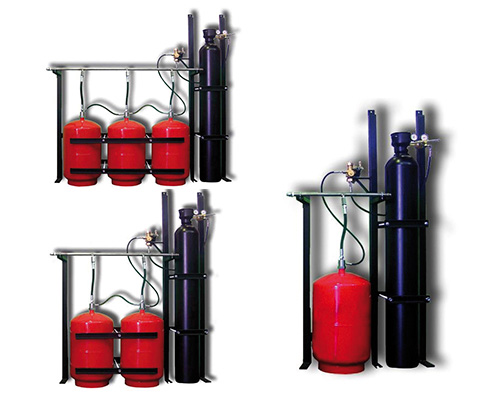

Row formed with bottles manufactured in stainless steel AISI 316 with welding accordingto MIE AP5 instruction about appliances under pressure and built for a 40 bar working pressure.

Composed with bottles filled with water at atmospheric pressure, equipped with valvefor nitrogen input and water output and bottles filled with nitrogen (N2) at 200 bar, equipped with main valve, provided with:

- Electric solenoid for automatic triggering.

- Lever for manual triggering.

- Manometer, transducer, hose and other accessories.

- Assembled in a metal frame with double iron fittings for fixation of the bottles, collector of discharge with coupling thread to the installation and discharge hoses.

| Reference | Bot. de H2O | Bot. de N2 | Water(L) | Dimensions |

| AN/BIN170 | 1 | 1 | 70 | 1250X1700X450 |

| AN/BIN270 | 2 | 1 | 140 | 1500X1700X450 |

| AN/BIN370 | 3 | 1 | 210 | 1950X1700X450 |

| AN/BIN470 | 4 | 2 | 350 | 3050X1950X450 |

| AN/BIN570 | 5 | 2 | 420 | 3500X1950X450 |

| AN/BIN670 | 6 | 2 | 490 | 4200X1950X450 |

| AN/BIN770 | 7 | 3 | 490 | 4200X1950X450 |

| AN/BIN870 | 8 | 3 | 560 | 4650X1950X450 |

| AN/BIN970 | 9 | 3 | 630 | 5050X1950X450 |