High pressure bottles, made of thermally treated alloyed steel, without welding (according to the MIE AP7 instruction about equipment under pressure and the 84/525/CEE European directive). Working pressure of 60 bars, pressure test of 250 bars, serving temperature of -20 °C to + 50 °C, engraved and painted in red color (RAL 3002).

Equipped with:

- Main valve made of forged brass with a piston and an axle in stainless steel, without welding. Equipped with disk security. CE marked, according to certificate.

- Relief valve to prevent triggering the process in the event of leakage.

- Safety bindings by iron fittings.

- Siphon tubes.

- Solenoid for triggering (powered by 24 V and at 500 mA of consumption).

- Flange and valve’s protective caps and its accessories.

| REFERENCE | CAP. L | MAX. LOAD(KG) | DIMENSIONS | LOAD (KG) |

| AEX/FE140S | 140 | 120,4 | 0,55×0,38×1,91 | 150 |

| AEX/FE120S | 120 | 103,2 | 0,55×0,38×1,68 | 135 |

| AEX/FE80S | 80 | 68,8 | 0,37×0,30×1,82 | 93 |

| AEX/FE67S | 67 | 57,6 | 0,37×0,30×1,62 | 79 |

| AEX/FE40 | 40,2 | 34,5 | 0,33×0,23,1×1,32 | 52 |

| AEX/FE26 | 26,8 | 23 | 0,33×0,23×1,02 | 48 |

| AEX/FE13 | 13,4 | 11,5 | 0,24×0,14×1,15 | 15,5 |

| AEX/FE6 | 6,7 | 5,7 | 0,24×0,14×0,65 | 10,3 |

| AEX/FE4 | 4,7 | 4,3 | 0,24×0,14×0,50 | 8,6 |

High-pressure bottles manufactured in thermally treated alloyed steel, without welding (according to the MIE AP7 instruction about equipment under pressure and the84/525/CEE European Directive). Working pressure of 60 bars, pressure test of 250bars, serving temperature from -20 °C to + 50 °C, engraved and painted in red colour (RAL 3002).

Equipped with:

- Main valve, manufactured out of forged brass with a piston and an axle in stainless steel, equipped with a security disc and a relief valve to avoid triggering in case of small spills.

- Siphon tube.

- Solenoid for triggering (powered by 24 V and at 500 mA of consumption).

- Micro-processed equipment of continuous weighing, where the weight of each bottleis individually controlled by analogue equipment. Mod.AEX/CPC.

- Programmable unit that detects the weight loss from 200 grams on, formed basically by: electronic cell, microprocessor and digital display reflecting the weight permanently. Supplied withtensor, which allows to easily raise the bottle, connectors with hoses assembled forits connection and rest of complements.

- Assembled in special metallic frame for continuous weighing, a discharge collectorwith a coupling thread, to the installation and a decompression valve.

Observations:

- A. The 80L and 120L bottles are supplied with a AE-250 valve of 2 1/2”. Equipped withiron fittings for fastening, flange and metallic hood for protection of the valve and itsaccessories during transportation.The bottles of 67, 40.2

and 26.8 L are supplied with the AE-160 valve of 1 1/2”.The bottles of 13.4, 6.7 and 4.7L are supplied with the AE-100 valve of 1”. - B. Each bottle has the corresponding certificates issued by the Ministry of Industryand they are available at the disposition of our customers in our archives.

| REFERENCE | CAP. L | MAX. LOAD(KG) | DIMENSIONS |

| AEX/SBP1140FE | 140 | 120,4 | 1×0,7×2,53 |

| AEX/SBP1120FE | 120 | 103,2 | 1×0,7×2,3 |

| AEX/SBP180FE | 80 | 68,8 | 1×0,45×2,5 |

| AEX/SBP167FE | 67 | 57,6 | 0,8×0,45×2,2 |

| AEX/SBP140FE | 40,2 | 34,5 | 0,8×0,45×2 |

| AEX/SBP126FE | 26,8 | 23 | 0,8×0,45×1,7 |

| AEX/SBP113FE | 13,4 | 11,5 | 0,8×0,45×1,8 |

| AEX/SBP16FE | 6,7 | 5,7 | 0,8×0,45×1,3 |

| AEX/SBP14FE | 4,7 | 4,3 | 0,8×0,45×1,2 |

H274 Metalwork for bottles from 4.7 to 13.4 L

H364 Metalwork for bottles from 26.8 to 50.3 L

H402 Metalwork for bottles from 67 to 80 L

H120 Metalwork for bottles of 120 L

HP274 Metalwork for pilot small bottle

L34 Hose for autonomous HFCs from 4.7 to 13.4 L (with or without weighing)

L114N Hose for HFC rows and bottles from 26.8L to 67L (with or without weighing)

L112N Hose for HFCs rows and bottles from 80 to 120L (with or without weighing)

LD18 Triggering hoses of rows from 67 and 80L

LD18-500 Triggering hose for rows of 120 and 140L

LD18BP Triggering hose for pilot small bottle

LD18BPP Triggering hose for pilot small bottle with weighing

LDR18 Hose of directional valve with backstop

V-CA Hood for the protection of CO2 bottles and HFCs bottles, of 4.7 to 67 L

V-CA212 Hood for the protection of bottles of 80, 120 and 140L

BRW80 Flange for fixing the hood of the bottles of 4.7 to 13.4 L

BRR112 Flange for fixing the hood of bottles of 26.8 to 67 L

BRR212 Flange for fixing the hood of bottles of 80 to140 L

AEX/BP Pilot small bottle of triggering of 5L loaded with CO2 (without weighing)

AEX/BPP Pilot small bottle of triggering of 5L loaded with CO2 (with weighing)

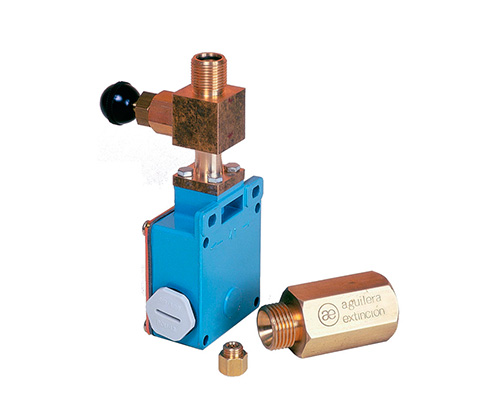

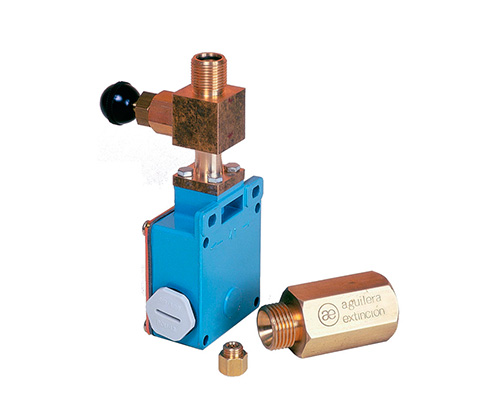

AEX/CP1 Let pass contactor

AEX/VAR112 Backstop valve of 1 1/2” HFC’S bot. of 80 and 140L

AEX/VA Relief valve

AEX/M160 Pressure gauge of 0-160 bars

AEX/PA Open pressure regulator

AEX/PC Closed pressure regulator

AEX/VS24 Auto triggering solenoid at 24 Vdc/500 mA

AEX/PM160A Lever of manual triggering for valve

AEX/VS24DR Solenoid for a directional valve

AEX/CPC2 Analogue unit for continuous weighing which incorporates: cell of electronic

charge, microprocessor, digital display and programming keys

AEX/CPCA Adapter for continuous weighing

AEX/LE Hose for entry with connector

AEX/LU Hose of union between equipment with connectors

AEX/LUBP Hose of union for pilot small bottle with weighing

AEX/LFL2 End-of-line connector

BPAS1 Subjection arc to the flange for bottle of 67L

BPAS80-1 Subjection arc to the flange for bottles of 80 to 140 L

AEX/CPC3 Analogue unit for continuous weighing which incorporates: cell of electroniccharge, microprocessor, digital display and programming keys

AEX/DCH112C calibrated of 1 1/2” female

AEX/DCH114C calibrated of 1 1/2” female

AEX/DCH1C calibrated of 1” female

AEX/DCH34C calibrated of 3/4” female

AEX/DCH12C calibrated of 1/2” femalea

AEX/DCH38C calibrated of 3/8” female

AEX/DR112C of 1 1/2” female

AEX/DR114C of 1 1/4” female

AEX/DR1C of 1” female

AEX/DR34C of 3/4” female

AEX/DR12C of 1/2” female

AEX/DR38C of 3/8” female

AEX/DR14C of 1/4” female

AEX/DV112C calibrated of 1 1/2” female

AEX/DV114C calibrated of 1 1/4” female

AEX/DV1C calibrated of 1” female

AEX/DV34C calibrated of 3/4” female

AEX/DV12C calibrated of 1/2” female

AEX/DV38C calibrated of 3/8” female

AEX/VCODR34 Directional valve of 3/4”

AEX/VCODR1 Directional valve of 1”

AEX/VCODR114 Directional valve of 1 1/4”

AEX/VCODR112 Directional valve of 1 1/2”

AEX/VCODR2 Directional valve of 2”

AEX/VCODR212 Directional valve of 2 1/2”

AEX/VCODR3 Directional valve of 3”

AEX/VCODR4 Directional valve of 4”

AEX/SDR2 Triggering system for 2 directional valves

AEX/SDR3 Triggering system for 2 directional valves

AEX/VFE100S AE-100 valve with solenoid (autonomous)

AEX/VFE160 Valve AE-160 slave for rows

AEX/VFE160S AE-160 valve with solenoid (autonomous)

AEX/VFE250 Valve AE-250 slave for rows

AEX/VFE250S AE-250 valve with solenoid (autonomous)

High-pressure rows formed by bottles of 67, 80, 125 and 140 L of capacity each. Manufacturedout of thermally treated steel, without welding (according to the MIE AP7 aboutequipment under pressure and the 84/525/EEC European directive).

Working pressureof 42 bars, test pressure of 250 bars, serving temperature of -20 °C to + 50 °C, engraved and painted in red colour (RAL 3002).

Equipped with:

- Main valve with pneumatic opening through the head.

- Backstop valves.

- Hoses for pneumatic activation of triggering and hoses for discharge.

- Assembled in metal frame double crossbar for fixation and collector of discharge,withcoupling flange to the installation and a decompression valve.

- The frames are manufactured for mounting the bottles, in either one or two rows.

Observations:

- A. Up to 9 bottles, the pneumatic triggering of the row takes place by converting oneof the bottles into a pilot bottle, for which its solenoid valve is equipped with automatictriggering and for manual triggering, a lever.

- B. From 10 bottles on, the rows are equipped with a pilot triggering bottle, consistingof a 5 L bottle loaded with CO2, filled with a main valve of 1″, solenoid at 24V forautomatic triggering and lever for the manual triggering.

| REFERENCE | Nº BOT. | CAP. (L) | MAX. LOAD(KG) | DIMENSIONS |

| AEX/SBFE267 | 2 | 134 | 115,2 | 1,24×0,35×2,34 |

| AEX/SBFE367 | 3 | 201 | 172,8 | 1,58×0,35×2,34 |

| AEX/SBFE467 | 4 | 268 | 230,4 | 1,92×0,35×2,34 |

| AEX/SBFE567 | 5 | 335 | 288 | 2,26×0,35×2,34 |

| AEX/SBFE667 | 6 | 402 | 345,6 | 2,6×0,35×2,34 |

| AEX/SBFE767 | 7 | 469 | 403,2 | 2,94×0,35×2,34 |

| AEX/SBFE867 | 8 | 536 | 460,8 | 3,28×0,35×2,34 |

| AEX/SBFE967 | 9 | 603 | 518,4 | 3,62×0,35×2,34 |

| AEX/SBFE1067 | 10 | 670 | 576 | 3,96×0,35×2,34 |

| AEX/SBFE1167 | 11 | 737 | 633,6 | 4,3×0,35×2,34 |

| AEX/SBFE1267 | 12 | 804 | 691,2 | 4,64×0,35×2,34 |

| AEX/SBFE1367 | 13 | 871 | 748,8 | 4,98×0,35×2,34 |

| AEX/SBFE1467 | 14 | 938 | 806,4 | 5,32×0,35×2,34 |

| REFERENCE | Nº BOT. | CAP. (L) | MAX. LOAD(KG) | DIMENSIONS |

| AEX/SBFE280 | 2 | 160 | 137,6 | 1,60×0,35×2,69 |

| AEX/SBFE380 | 3 | 240 | 206,4 | 1,94×0,35×2,69 |

| AEX/SBFE480 | 4 | 320 | 275,2 | 2,28×0,35×2,69 |

| AEX/SBFE580 | 5 | 400 | 344 | 2,62×0,35×2,69 |

| AEX/SBFE680 | 6 | 480 | 412,8 | 2,96×0,35×2,69 |

| AEX/SBFE780 | 7 | 560 | 481,6 | 3,3×0,35×2,69 |

| AEX/SBFE880 | 8 | 640 | 550,4 | 3,64×0,35×2,69 |

| AEX/SBFE980 | 9 | 720 | 619,2 | 3,98×0,35×2,69 |

| AEX/SBFE1080 | 10 | 800 | 688 | 4,32×0,35×2,69 |

| AEX/SBFE1180 | 11 | 880 | 756,8 | 4,66×0,35×2,69 |

| AEX/SBFE1280 | 12 | 960 | 825,6 | 5×0,35×2,69 |

| AEX/SBFE1380 | 13 | 1040 | 894,4 | 5,34×0,35×2,69 |

| AEX/SBFE1480 | 14 | 1120 | 963,2 | 5,68×0,35×2,69 |

| REFERENCE | Nº BOT. | CAP. (L) | MAX. LOAD(KG) | DIMENSIONS |

| AE/SBFE2120 | 2 | 240 | 206,4 | 1,75×0,45×2,44 |

| AE/SBFE3120 | 3 | 360 | 309,6 | 2,19×0,45×2,44 |

| AE/SBFE4120 | 4 | 480 | 412,8 | 2,63×0,45×2,44 |

| AE/SBFE5120 | 5 | 600 | 516 | 3,07×0,45×2,44 |

| AE/SBFE6120 | 6 | 720 | 619,2 | 3,51×0,45×2,44 |

| AE/SBFE7120 | 7 | 840 | 722,4 | 3,95×0,45×2,44 |

| AE/SBFE8120 | 8 | 960 | 825,6 | 4,39×0,45×2,44 |

| AE/SBFE9120 | 9 | 1.080 | 928,8 | 4,83×0,45×2,44 |

| AE/SBFE10120 | 10 | 1.200 | 1.032 | 5,27×0,45×2,44 |

| AE/SBFE11120 | 11 | 1.320 | 1.135,2 | 5,71×0,45×2,44 |

| AE/SBFE12120 | 12 | 1.440 | 1.238,4 | 6,15×0,45×2,44 |

| AE/SBFE13120 | 13 | 1.560 | 1.341,6 | 6,57×0,45×2,44 |

| AE/SBFE14120 | 14 | 1.680 | 1.444,8 | 7,03×0,45×2,44 |